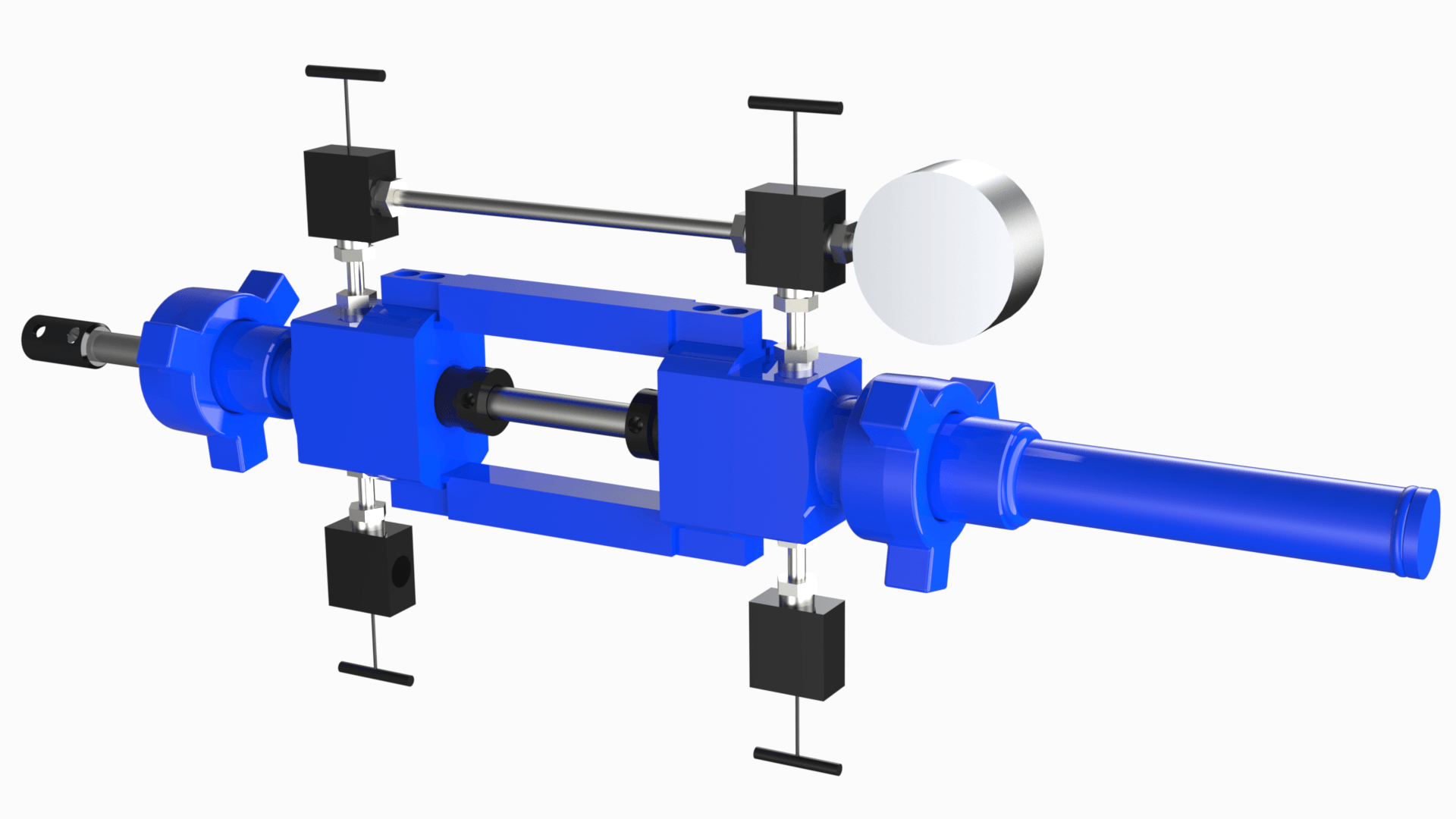

Well-Control Equipment

Wellhead Equipment & Component Manufacturer

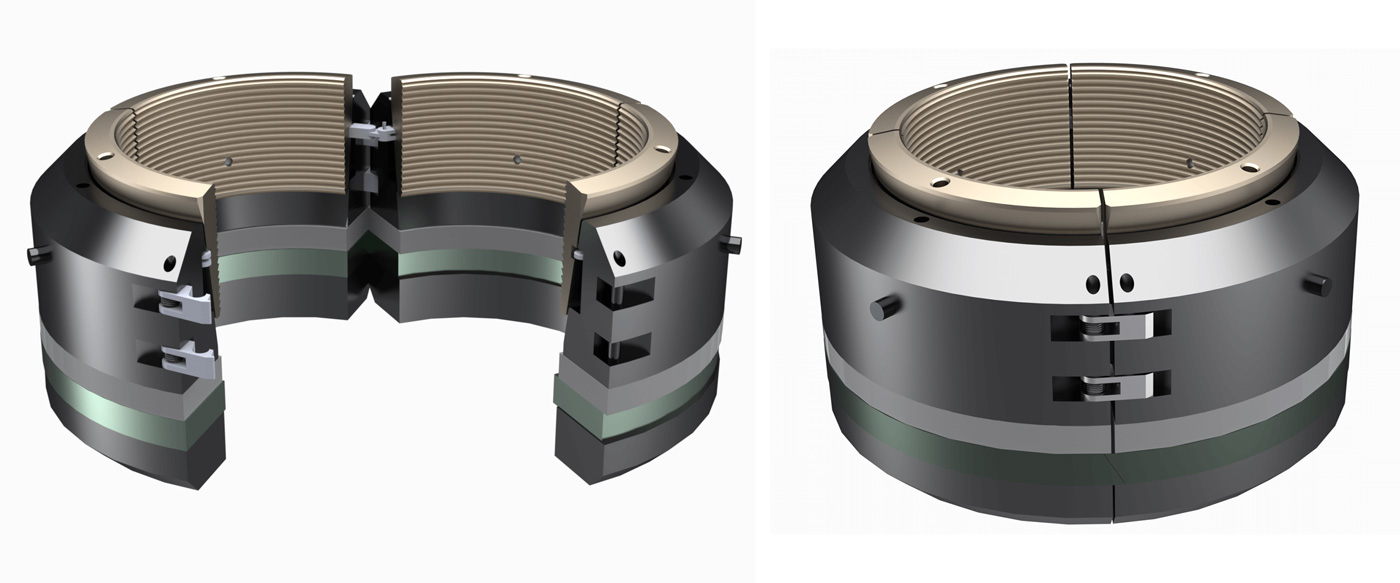

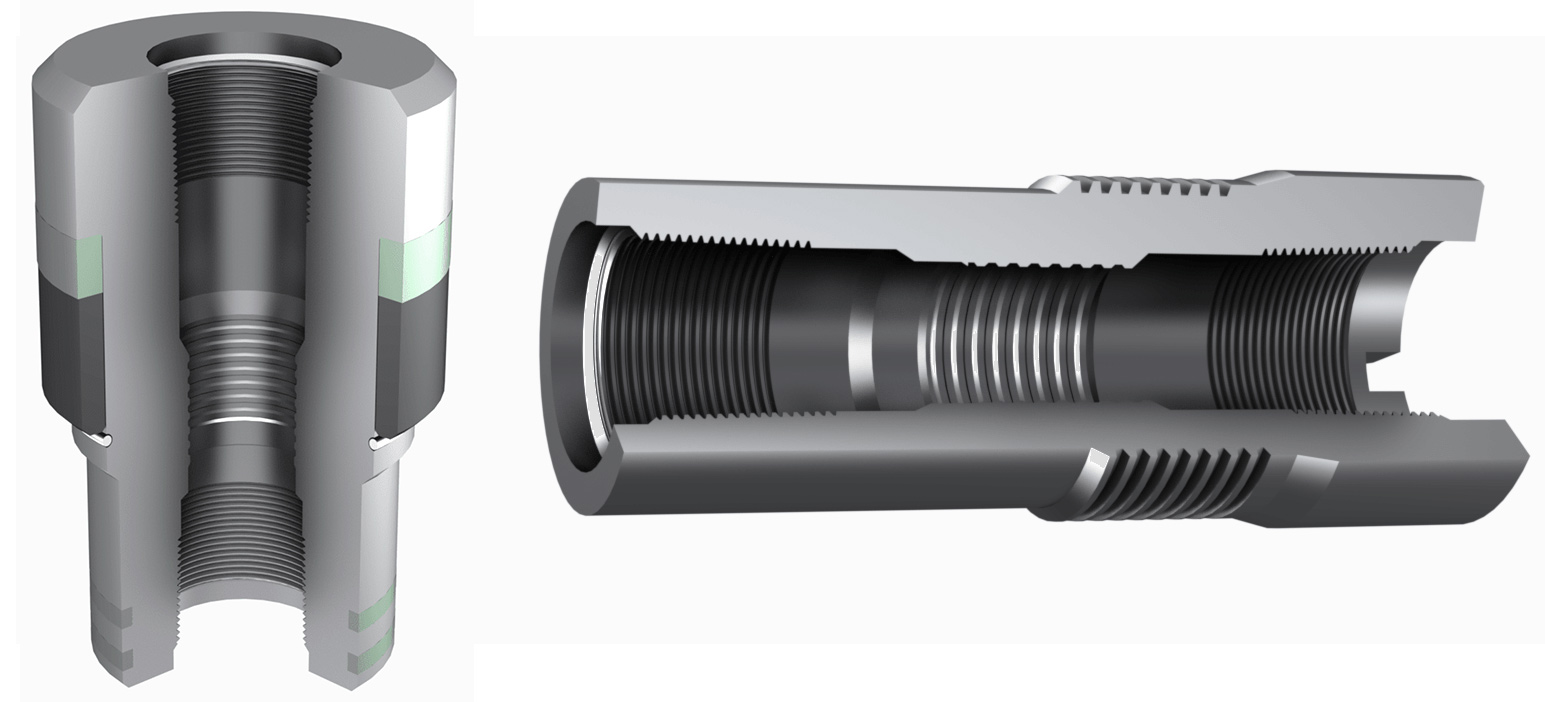

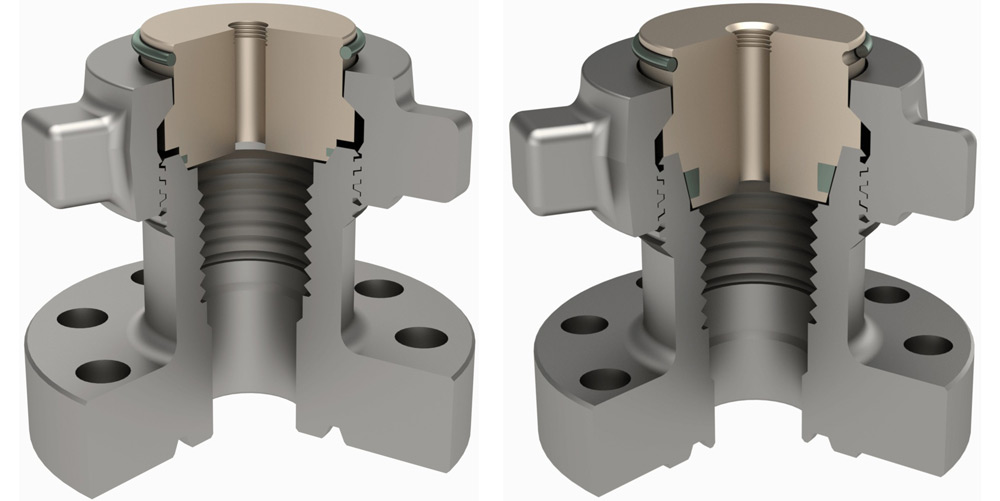

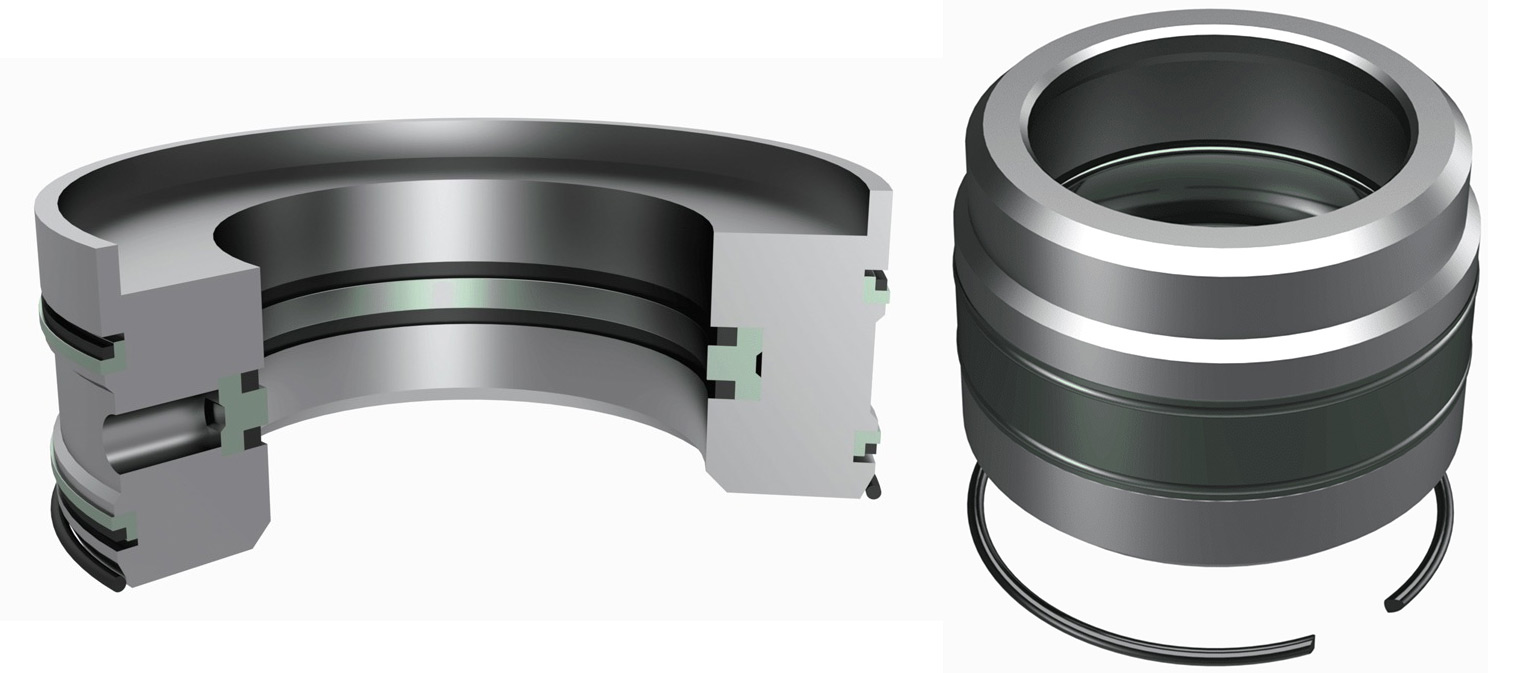

Established in 1986, GB Industry has over three decades of experience in manufacturing Wellhead and Well-Control Equipment per custom and standard specifications - Casing Hangers, Back Pressure & Two-Way Check Valves, BPV and VR Lubricators, Tubing Hangers, Bottom Hole Test Adapters, and Primary & Secondary Seals. GBI quality management system conforms to API Specifications Q1 with a manufacturing base in Pearland, Texas, south of Houston. GBI personnel form reliable and experienced professionals to serve our customers product and service needs for Oil & Gas wellhead equipment.

Our Wellhead Equipment & Component Products

Have a question? our experts can help you!

Our Services

Milling

Our CNC milling equipment and in-house expertise offer a one-stop-shop for precise milling services per OEM requirements.

GBI’s five vertical CNC centers allow us to manufacture competitive small to large parts in low and high-volume production. Our largest milling table is 82” x 26” with 69” x 26” x 26” XYZ travels. Our machines are equipped with user-friendly CNC controls, probing, and temperature stability through cooling.

GBI uses the latest Mazak mills developed with advanced program functions to maximize performance and productivity.

Turning

As a leader in Oil & Gas Wellhead Equipment & Component Manufacturer for over 30 years, GBI developed extensive in-house expertise on precision CNC turning parts per most wellhead manufacturers' requirements.

Our sixteen CNC turning centers allow us to manufacture competitive small to large parts in low and high-volume production. Our turning is 1/8" - 36" in diameter with up to 8” through spindle and 62” maximum distance between tailstock and chuck.

GBI uses the latest Mazak turning centers that combine milling and turning technology to maximize productivity and flexibility. Also, two lathes are equipped with automatic bar feeders to optimize productivity.

CNC Machining

GBI uses Computer Numerical Control (CNC) machines for precision manufacturing per API specifications for Oil & Gas Wellhead products.

We can solve any manufacturing issues with our in-house expertise in programming and operating computer-controlled machines. GBI in-house CNC programming uses MAZAK MAZATROL CNC Controls technology developed for conversational and EIA/ISO programming.

GBI CNC machining services offer accuracy, on-time delivery, and versatile production rates at a competitive cost.

Turnkey Manufacturing

GBI offers Ready-to-Operate Oil & Gas Wellhead products through with in-house turnkey manufacturing process – design, engineering, procurement, manufacturing, assembly, testing, and delivery.

GBI turnkey manufacturing benefits

- High Quality

- On-Time Delivery

- Cost-Effective product.

With GBI’s turnkey manufacturing, low and high-volume production and custom requirements are easy – design and manufacturing in-house, making communication within engineering, manufacturer, and assembly.

Hydrotesting

Hydrostatic pressure testing is used to verify wellhead equipment for leaks and structural integrity. It is performed by filling the system with water, pressurizing it up to a required level, and monitoring for pressure drops during a specified amount of time.

GBI performs hydrostatic testing for surface wellhead products per API 6A latest standard edition.

Our hydrostatic capability

- Pressure rating up to 30,000 psi

- In-house designed fixtures

- Dedicated hydro-testing booth and specialized personnel

- Tested wellhead components BPVs & TWCVs, Flanges, Top Connectors and Manual Lubricators.

Engineering Services (Design)

A fast-track ability to design, test, manufacture, and assemble field-proven Surface Wellhead and Completion equipment give GBI a leading position in the wellhead market.

Our in-house design and engineering capabilities allow us to provide custom equipment to interface with other brands of wellhead equipment, all within short lead times. Many Oil & Gas wellhead manufacturers rely on GBI to provide custom design to work with their equipment.

GBI’s wide variety of field-proven surface wellhead products such as casing hangers, back pressure valves BPV, two-way check valves TWCV, lubricators and more are engineered and manufactured to the API 6A latest standard edition – Specifications for Wellhead and Tree Equipment.

Our engineering department uses state-of-the-art CAE/CAD/FEA tools for design and analysis to develop concurrent design solutions with CAM/CNC manufacturing in-house.

Contact Us Today

Shipping Address

2019 Country Road 124

Pearland, TX 77581

Mailing Address

PO Box 1622

Friendswood, TX 77549